Here are the main problems:

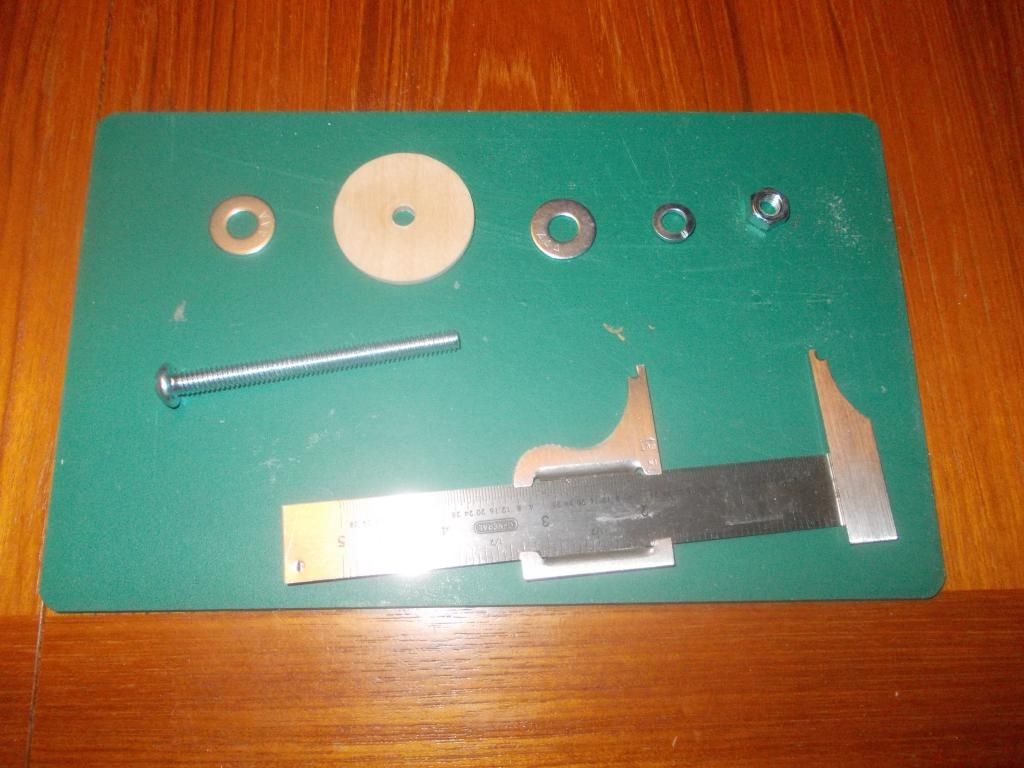

My early attempt at thrust adjustment consited of taping a piece of wood under the thrust button. And removing and attaching the cowl is very tedious under field conditions. I started to remove my old support system and will contruct new.

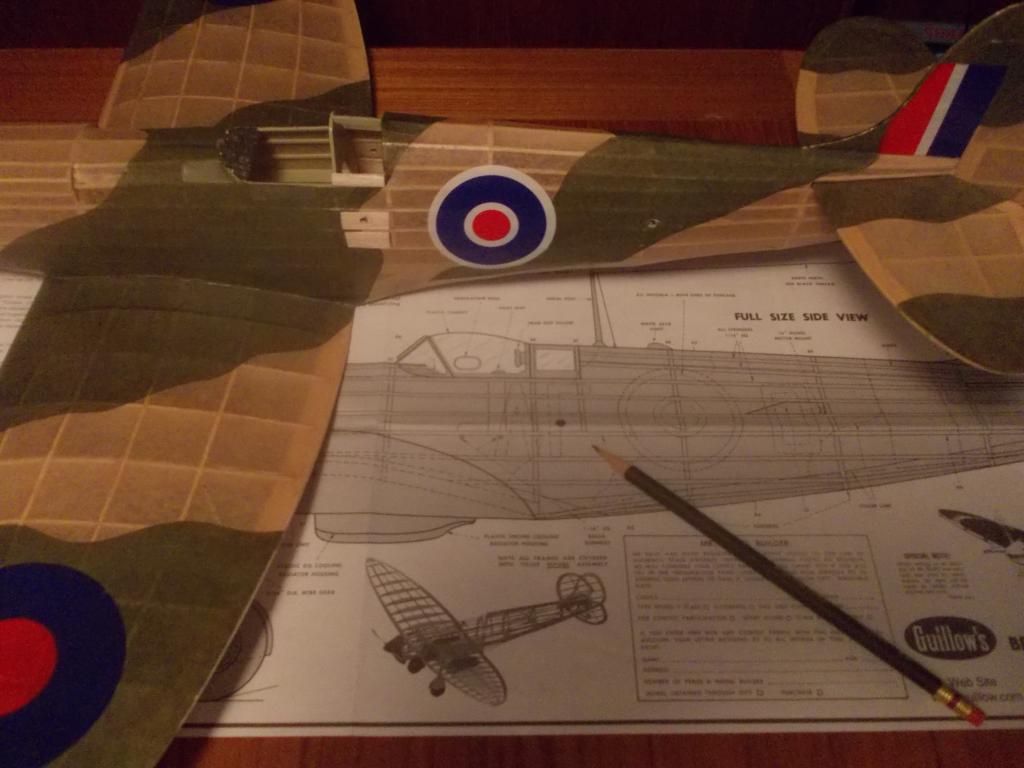

I had to purchase 1 more hole saw as the front end of the Spitfire is even smaller than the Messerschmitt.

You can see the disadvantage I am at. The large firewall is for the 1000 series Thunderbolt!

I also plan to move the rear peg forward 5 inches!

In future builds, this will allow me to lighten the rear of the airplane MUCH more!

This current model weighs 80 grams, but the cowl and ballast are 40 grams... a total of 120 w/o prop and rubber. I will attempt in the future to have the AUW of the NEW Spitfire to be no more than 80 grams!

Mitch

PS: But now I am off to dance class...the ladies will be waiting... I will continue work on the Spitfire after...