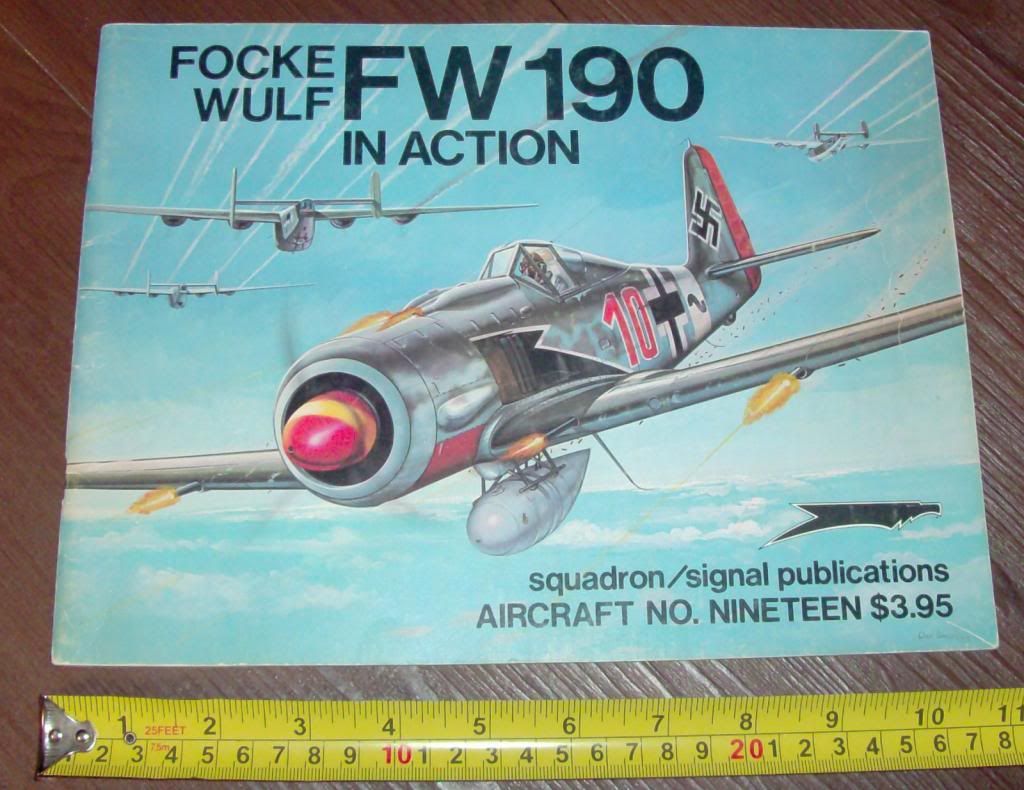

With my experience from WESTFAC and your advice... I see I need to make changes in my tame FW190 to make it a "Butcher Bird"... I will need to rebuild this kit as there are some things that need to be built into the model... But I plan to work with what I have to make this plane better.

First a few things I learned at WESTFAC... for competition...

1. Wing construction: USE LESS RIBS... I know you all told me this... Now that I have seen other models, I know what I need to do.

2. Dihedral: Wingtip can come up to bottom of cockpit. That means I can increase about 1 INCH! That is huge!

3. Motor mount: Move forward from what is shown on plans.

4. Compound Interest: The more you save in the tail construction will be compounded for ballast savings!

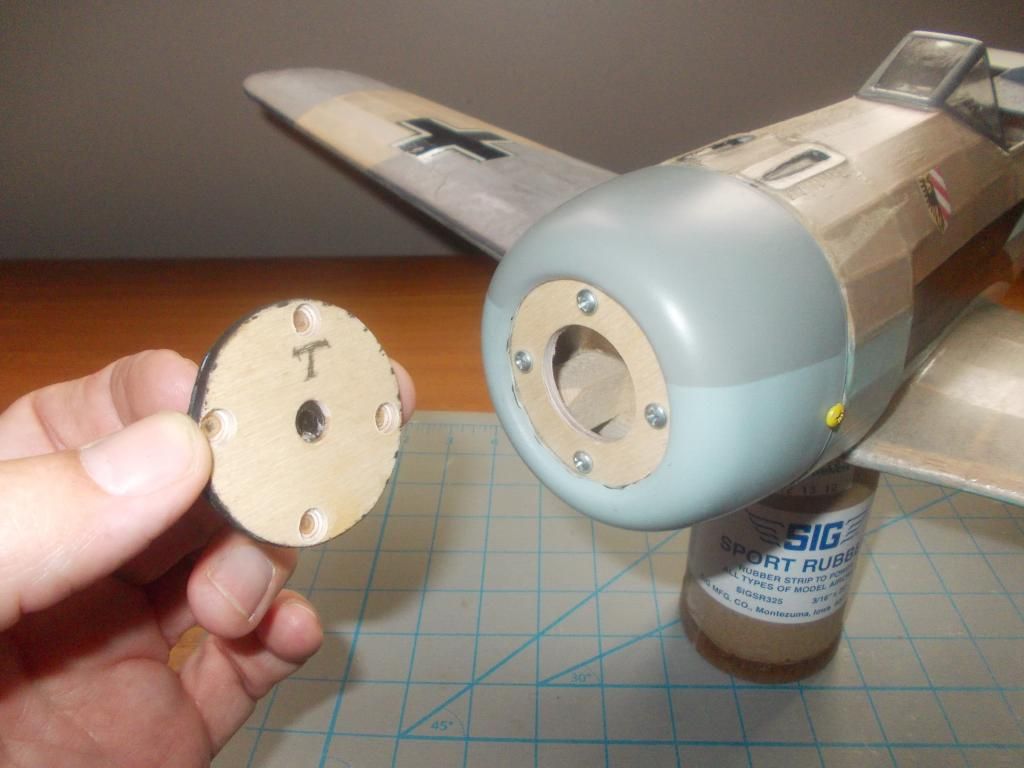

5. Thrust Bearing: I am reworking the front end to have the motor mount adjustable.

There is a whole lot more, but those are a few basics...

1 and 2 will go into my next FW 190 along with hand cut 1/32 ribs!

3. I removed the paper and motor mount and moved it up 2 bays.

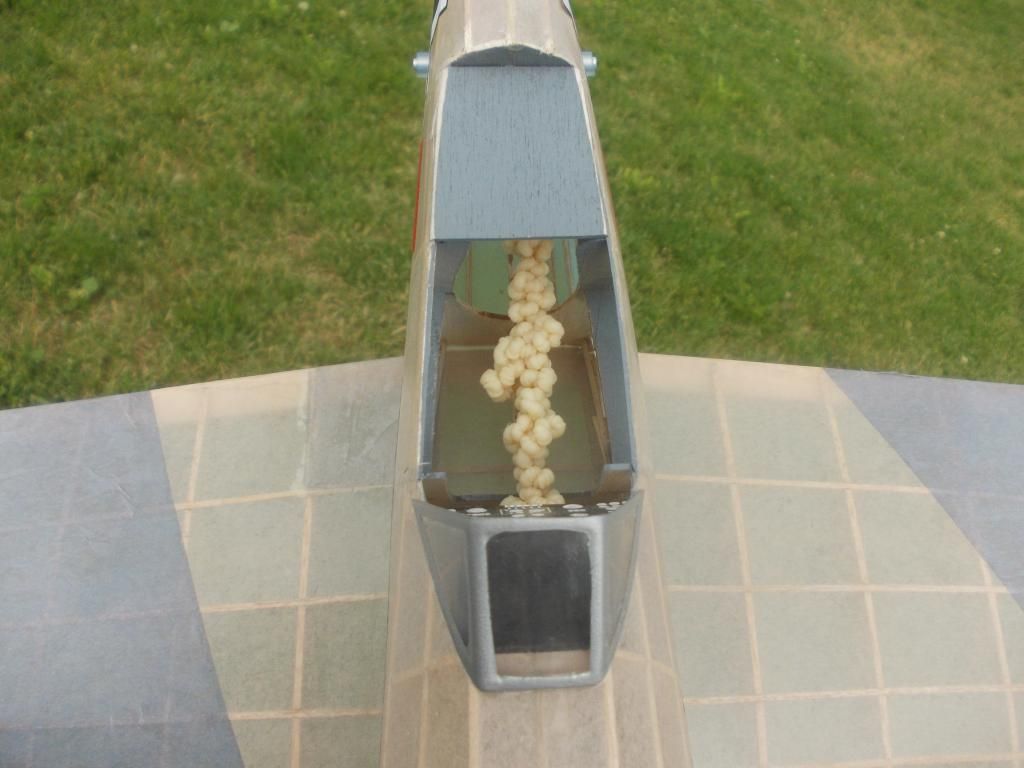

4. I rebuilt the tail. In the past, I tried to save weight by sanding the parts thinner, this resulted in potato chips for tail... Now, I made my own parts as per Guillows plans and removed excess material, and kept the thickness.

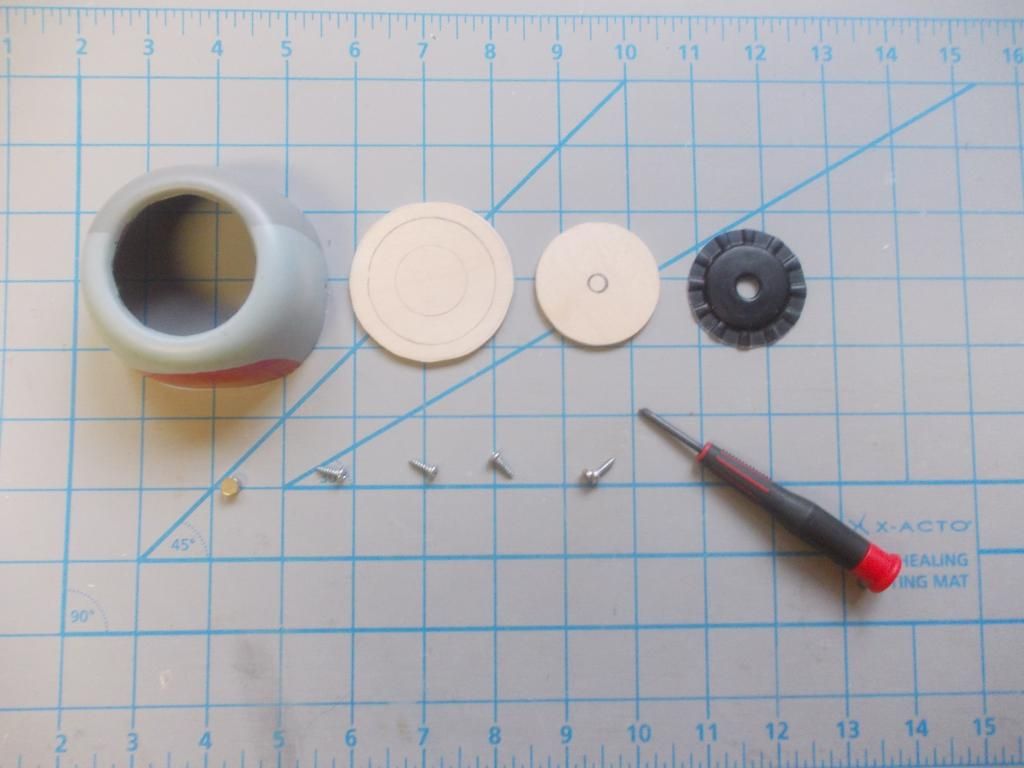

5. I opened up the cowling. I removed the cooling fan and will make a backup plate and then have 4 screws in that for thrust adjustment. I am working on this today.

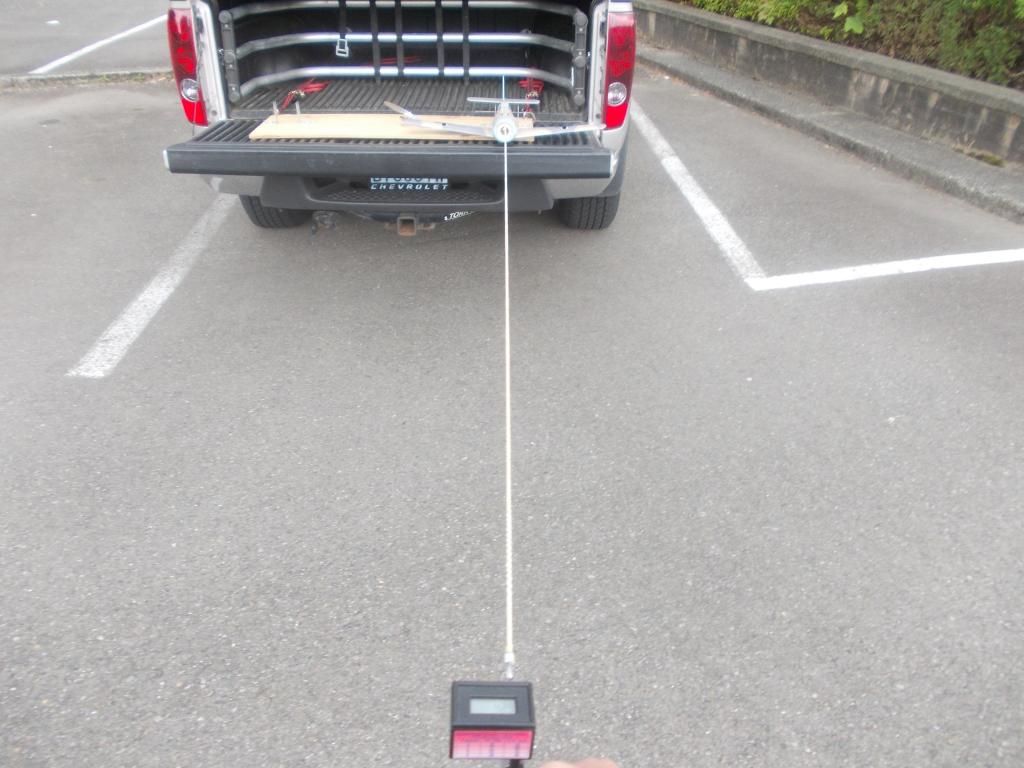

Staring Point:

Here is what I have now... I turned "White" 7 into "Red" 7:

Here is the close up of the tail...

...and...

The motor Mount:

the peg is now 1/8 inch aluminum tube, with medium fuel hose on ends to hold in place.

And the work for today is re-working the front end...

To avoid my new tail from becoming a potato chip I decided NOT to wet and shrink the paper. I put it on dry and got it as tight as I could. Now it has one coat of dope but it is not as tight as I like... Is there a better way to do this? I remember some of you said DO NOT wet the tail, only dope.

The tail is not too bad, but it is not as "tight as a drum"

The swastika is bond paper...so I can put on another coat of dope. Will that help?

Mitch