I am taking a break from wing construction and though I would post...

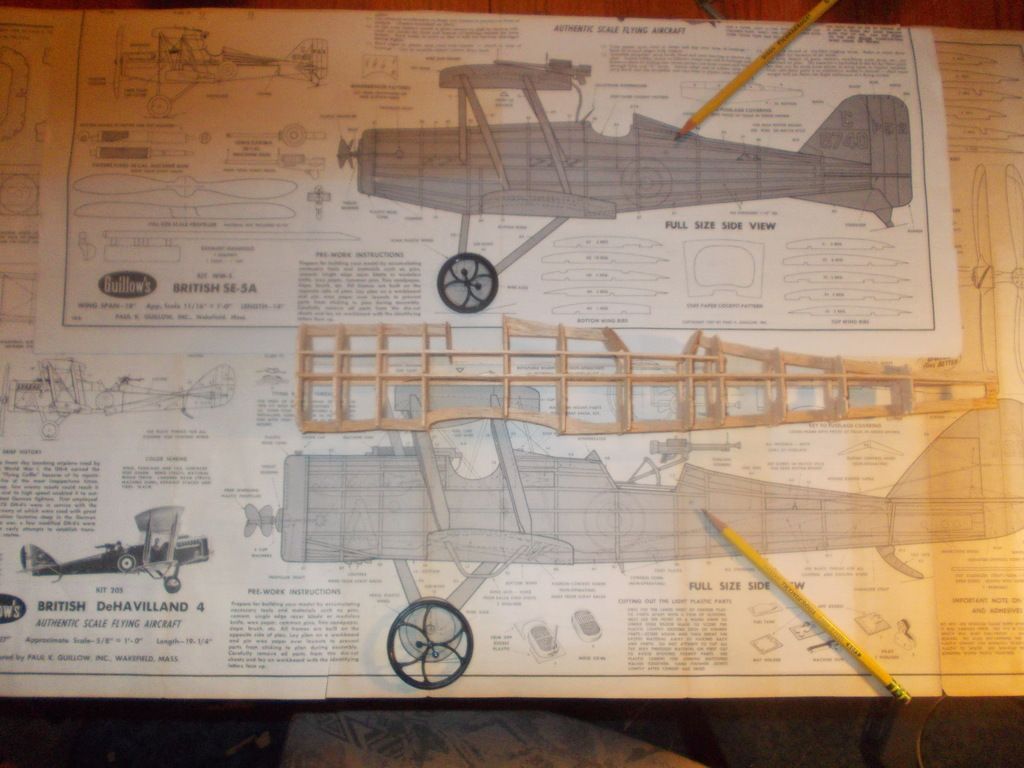

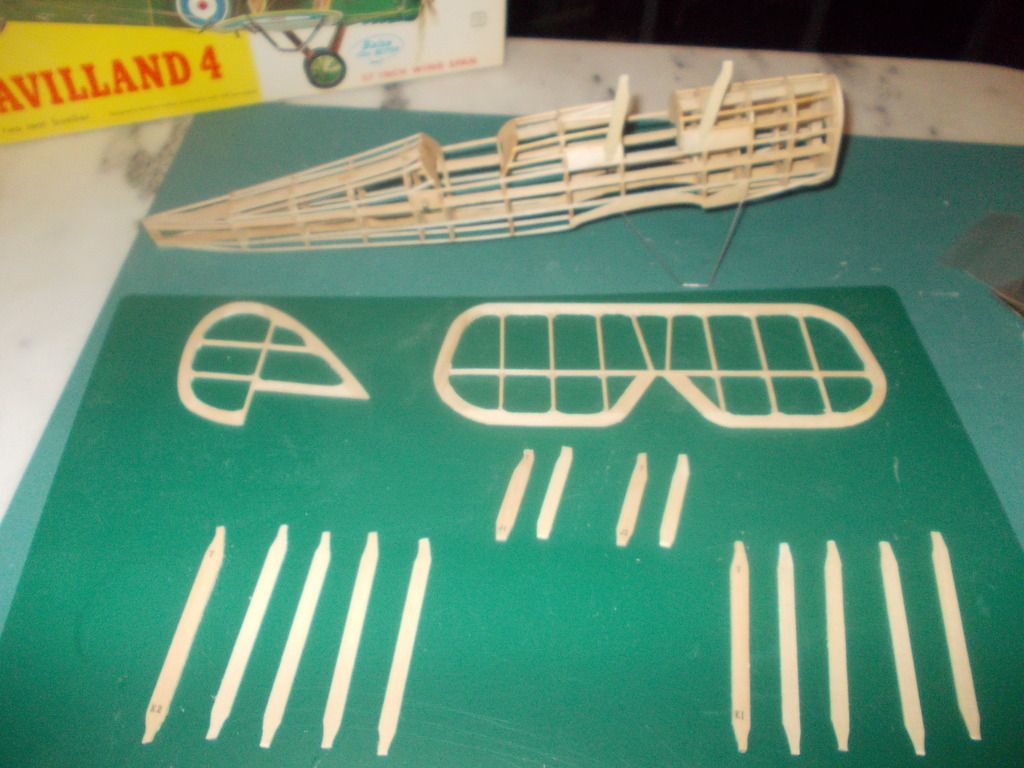

I decided to share what I have learned and how I am building this OOP kit! I built this when I was about 12 y/o, and could not get her to fly... well with the recent flight of my OOP kit the SE5, I am starting over on the DH4! I will not post a step by step build, but show you how I make improvements to make this model fly... on a rubber motor... I hope!

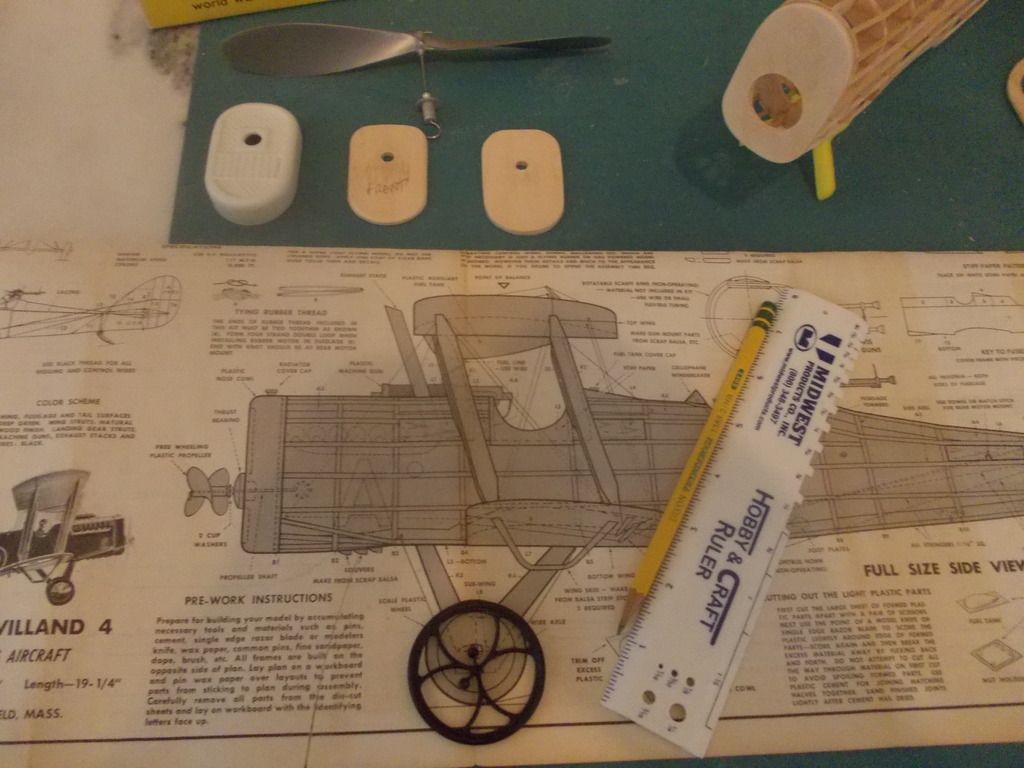

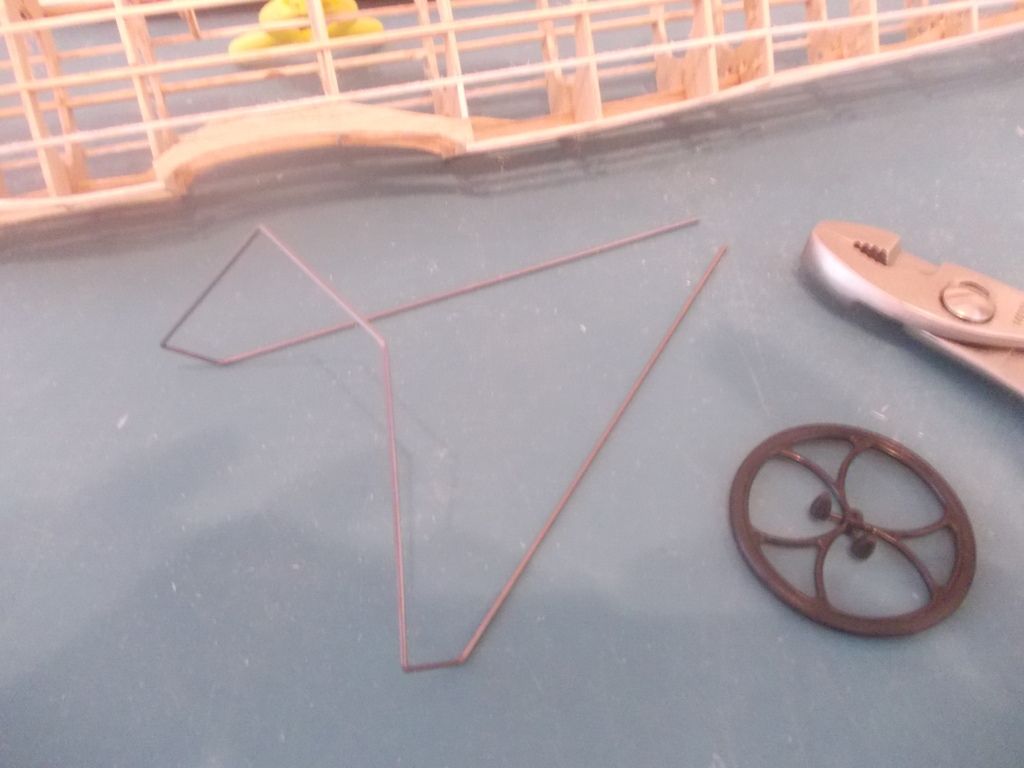

First off the tools:

Most important is information. If you do not belong to a club, or have Don Ross' book, I will share what I can here! If I just build the model as I did before I will have similar results... I plan to do better. Here all of my cutting tools. No.11 blades with tool, Straight Razor Blades, and a Razor Saw are most important.

I recently acquired 2 tools which are helpful but not absolutely necessary... The balsa stripper and small block plane. These are both made by Master Airscrew Windsor Propeller Co. They cost less than 5 dollars each and I bought them at my LHS.

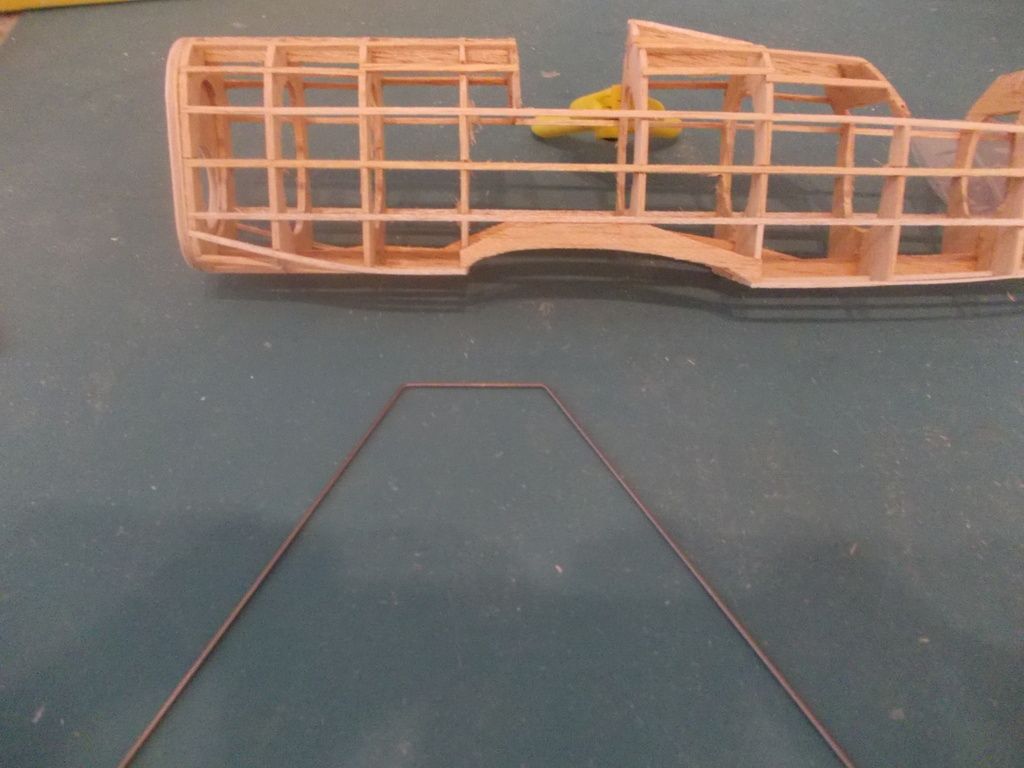

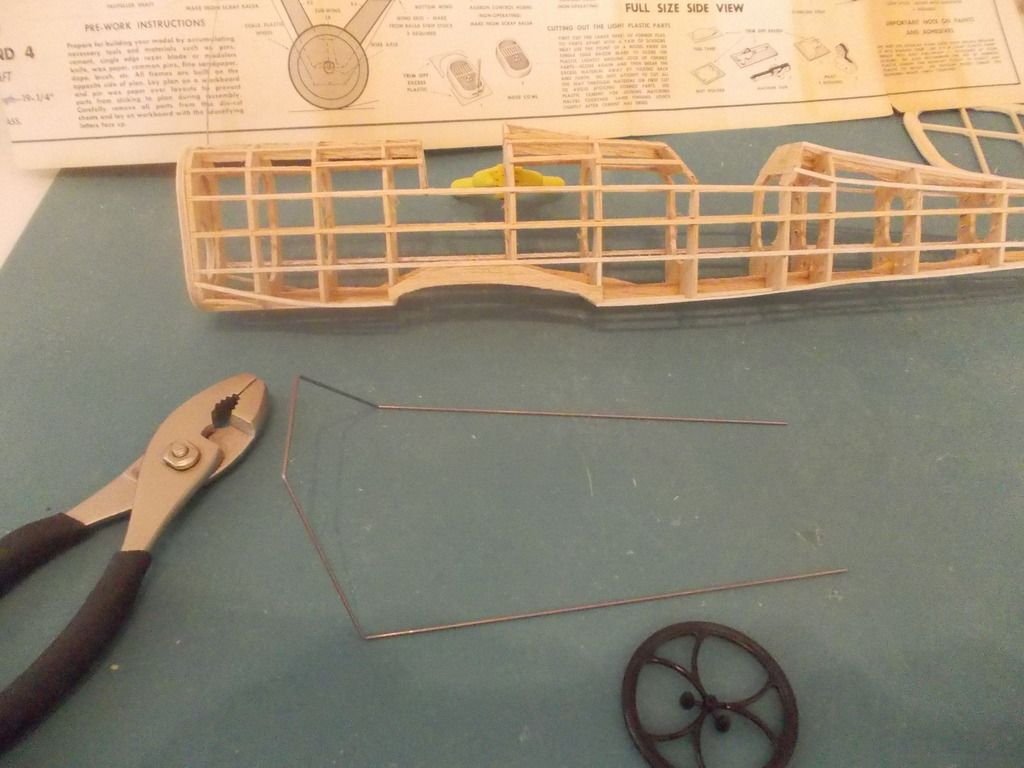

Well its day 2 and the wings are almost done... I will post pictures tomorrow and I am already saving weight! I plan to lighten the fuselage, and make a bent balsa rudder, the tail will be from contest wood, and she will have a bigger prop and motor!

See you tomorrow! Mitch